Sizing and Standards

Sizing & Standards

At Arbortec we like to have fun with clothes but when it comes to sizing and standards, we take things very seriously as it is critical to have the correct fitting PPE. To help you find the perfect fitting for clothes, chainsaw trousers and chainsaw boots, we’ve put together an easy-to-use sizing guide below.

For best fit, ensure you measure over light weight clothing.

If you have any other queries about our sizing, feel free to drop our Customer Xcellence Team a call on 01553 768346. We’re always happy to help.

Measuring Guide

Chest

For your chest size place a tape measure under the arms (over the shoulder blades) around the fullest part of the chest, but don't pull too tightly

Waist

Measure around the natural waist

Leg Length

Hold one end of your tape measure to your crotch point and measure down to your ankle bone

Men's Body Measurement Chart - Chest

Women's Body Measurement Chart - Chest

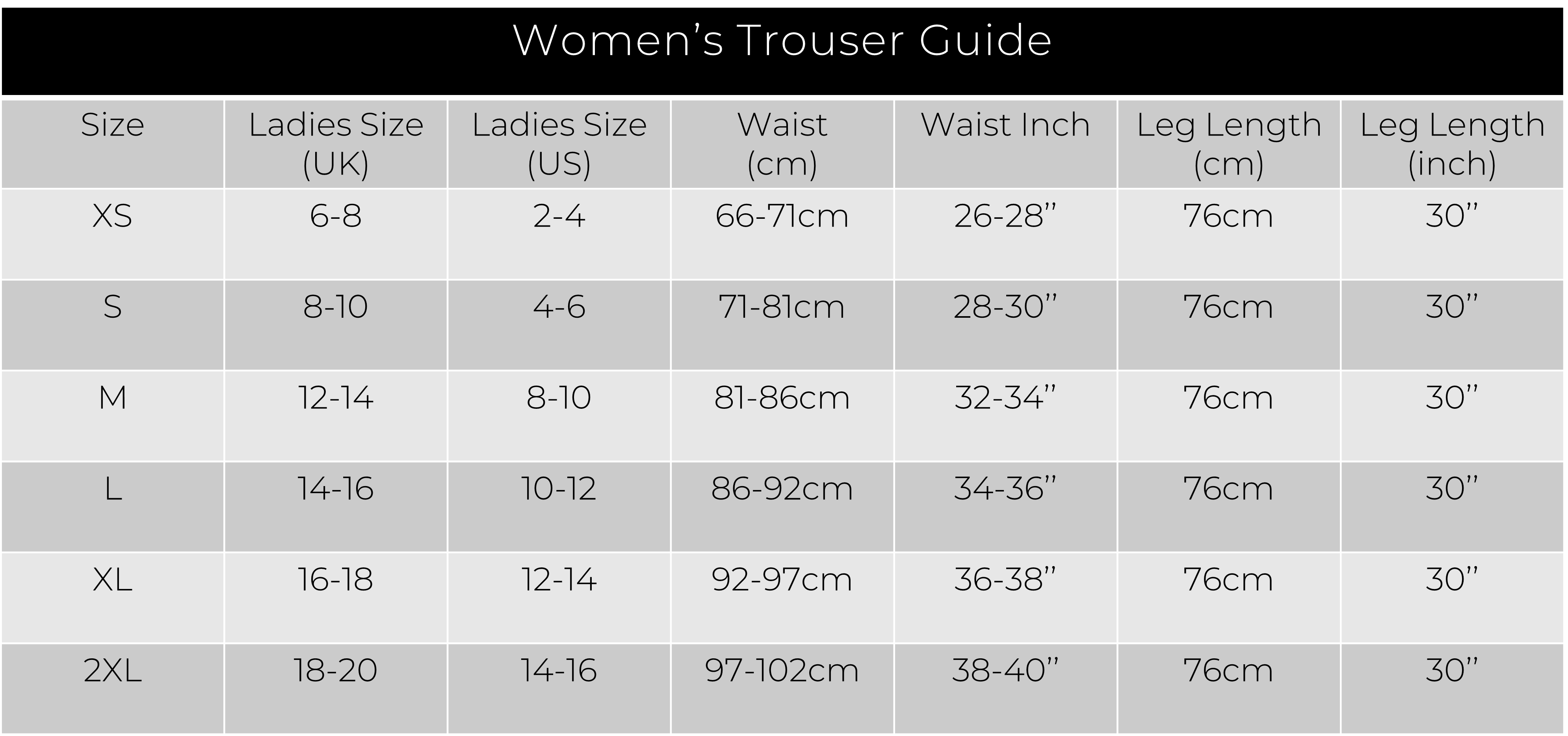

Trousers

Difference between Breatheflex Women's and Men's chainsaw trousers fitting:

When it comes to the fit of our women’s chainsaw trousers, there are some key differences between our women’s and men’s options. Firstly, the rise of the trousers is shorter in our women’s sizing, meaning they sit lower on the waist which is more flattering for the female shape.

Additionally, the leg shape is more tapered and narrower from the thigh down in women’s sizes, with the leg length being shorter by 3cm than the men’s regular length trouser.

The hips on our Women’s trousers are also wider to accommodate to female shaping, while the waist is similar in smaller sizes but becomes narrower from size M upwards to fit the female form.

Difference between the Breatheflex and the Breatheflex Pro trousers fitting:

While both trousers share identical leg length and waist width, the Breatheflex Pro offers a sleeker silhouette with a slimmer thigh that tapers down to the ankle.

This results in an overall narrower leg, coupled with a lower rise that rests comfortably on the lower waist. One of the standout features of the Breatheflex Pro is its improved fit, as the reduced fabric around the thigh to ankle area and lower positioning on the waist prevent any excess fabric in the crotch area. This results in a polished, modern fit that combines style and functionality seamlessly.

Difference between the Breatheflex Pro and the Freestyle trousers fitting:

The difference between our Breatheflex Pro trousers and Freestyle lies in their unique characteristics. Both styles share a comparable rise, sitting comfortably on the lower waist. However, the Freestyle trousers stand out with their distinct feature of offering more room around the thighs.

The rest of the leg on the Freestyle shows a slimmer profile, the combination of a spacious thigh area and a sleeker leg summarises the essence of the Freestyle trousers, blending comfort and contemporary design.

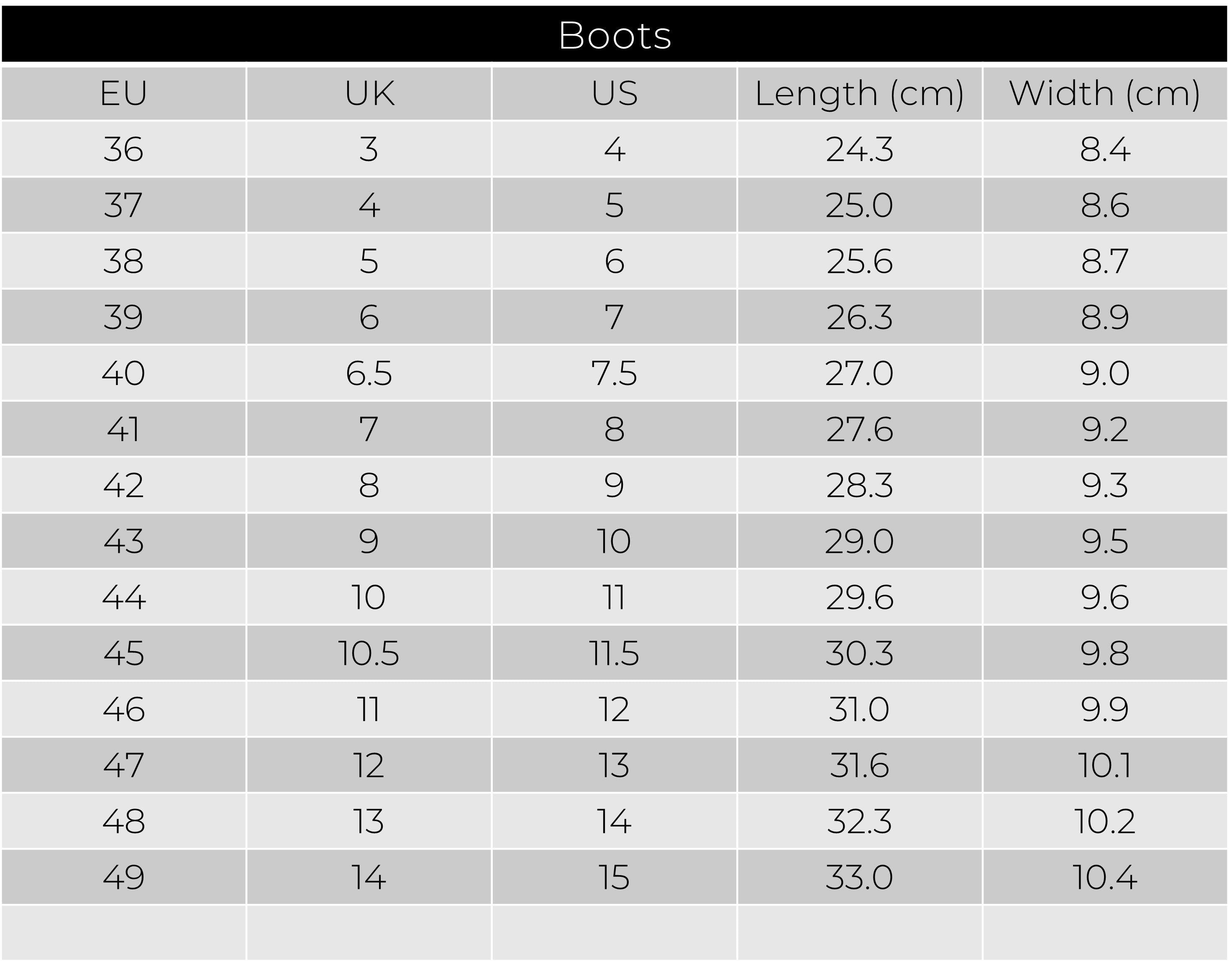

Boots

Foot Length

For best results, measure while bearing weight on your foot (and measure both feet to compare), measure from your heel to the top of your longest toe

Foot Width

Measure the widest part of your foot from left to right

Gloves

TO FIND OUT YOUR GLOVE SIZE:

Measure around your hand with a tape measure across your palm

Measure length from base of hand to tip of middle finger

Safety Standards

A chainsaw is possibly the most dangerous tool used in the woods, moving at 55-60 miles per hour or about 88 feet per second. However, with the correct protective equipment, any user can be kept safe. Non-chainsaw users may also need to wear appropriate PPE, for example, head, hearing or eye protection as identified in the task risk assessment.

It should be noticed that no PPE can guarantee complete protection against cuts from handheld chainsaws. There is no substitute for the correct training and safe work methods, but there are certain standards for what is legally required for protective chainsaw clothing based on local jurisdictions. Below is a brief outline of the standards cited on this website.

BS EN ISO 17249: 2004 Safety Footwear with Resistance to Chainsaw Cutting

This is a harmonised standard and includes many different tests.

As a minimum, to achieve this standard footwear must:

A) Comply with all the requirements of safety standard footwear (BS EN ISO 20345:2011)

B) Be tested for chainsaw resistance by standard BS EN ISO 11393-3:2018 (previously EN381-3)

BS EN ISO 11393-3:2018 (previously EN 381-3) Protective Clothing for Users of Handheld Chainsaws - Test Methods for Footwear

The BS EN ISO 11393 standard complies with protective clothing for chainsaw users.

This norm is divided into different parts (or designs). Each part treats a specific part of the body:

BS EN ISO 11393-3:2018 - Test methods and procedures for footwear. Footwear should be certified to the harmonised standard

BS EN ISO 11393-2:2019 (previously EN 381-5) Performance Requirements and Test Methods for Leg Protectors (the norm allows for 2 types or forms - Design A and Design C with different areas of protection)

DESIGN A

DESIGN C

BS EN ISO 11393-6:2019 Upper Body Protectors

BS EN ISO 11393-4:2019 Protective Gloves

BS EN ISO 11393-5:2019 Protective Gaiters

The norm also prescribes 4 classes that correspond to the chain speed with which the tests have been done:

Class 0 : 16 m/s

Class 1 : 20 m/s

Class 2 : 24 m/s

Class 3 : 28 m/s

BS EN ISO 20471:2013 +AI:2016 (formerly EN471) High-Visibility Clothing - Test Methods and Requirements

High-Visibility garment types are grouped into three classes based upon the conspicuity provided, with the classes dictating the minimum quantities of background and retro-reflective materials used.

CLASS 3 - Highest Protection Level of High Visibility Clothing

Band of retro-reflective material shall not be less than 50mm wide. Minimum background material 0.80m sq. Minimum retro-reflective material 0.20m sq.

CLASS 2 - Intermediate Protection Level of High Visibility Clothing

Band of retro-reflective material shall not be less than 50mm wide. Minimum background material 0.50m sq. Minimum retro-reflective material 0.13m sq.

CLASS 1 - Lowest Protection Level of High Visibility Clothing

Band of retro-reflective material shall not be less than 50mm wide. Minimum background material 0.14m sq. Minimum retro-reflective material 0.10m sq.

RIS-3279-TOM Issue 2:2019 High-Visibility Clothing for Rail (Formerly GO/RT 3279)

The RIS-3279-TOM Issue 2:2019 standard is based on the European standard EN ISO 20471:2013 & A1:2016. It requires garments to meet at least class 2 (the mid-point of a 3-class scale) of EN ISO 20471 for the minimum area of high-visibility materials used within a garment. Whereas the European standard permits several different colours of high visibility materials, the railway standard specifies an orange colour.

These fluorescent garments for night-time visibility feature retroreflective tapes.

Railway locomotive headlights pick out retro-reflective materials in high visibility clothing. Again, the railway standard draws on EN ISO 20471:2013 & A1:2016, and specifies materials for use that meet the highest level of photometric performance criteria that are specified within the standard

BS EN343:2019: Protective Clothing Protection Against Rain

BS EN343 is a European safety standard set to specify a minimum level of protection required from your workwear and PPE against foul weather. This standard takes into consideration the entire garment, as well as its fabrication to judge the level of protection it provides the wearer.

The certification is split into two categories the first, X judges precipitation, fog and ground humidity. The second, Y measures the garments breathability in those conditions.

Consequently, these categories are then rated from 1-4, with 4 representing the highest level of protection or breathability.

Therefore, a garment classified as EN343 4:4 means both the waterproofing and breathability are excellent providing the wearer with the highest level of protection from wind and rain.

BS EN388 2016 + A1:2018: PROTECTIVE GLOVES AGAINST MECHANICAL RISKS

BS EN388 2016 + A1:2018: PROTECTIVE GLOVES AGAINST MECHANICAL RISKS

BS EN 388 standard is used to test work gloves for a variety of properties. In brief, these properties are: cut resistance; tear resistance; abrasion resistance; puncture resistance and impact resistance. Gloves complying with BS EN388:2016+A1:2018 will display a pictogram as shown, with 5 or 6 characters relating to the properties shown below:

1st Character: Abrasion resistance (Numeral 1 to 4 with 4 being the best resistance)

2nd Character: Blade cut resistance (Numeral 1 to 4 with 4 being the best resistance)

3rd Character: Tear resistance (Numeral 1 to 4 with 4 being the best resistance)

4th Character: Puncture resistance (Numeral 1 to 4 with 4 being the best resistance)

5th Character: Further blade cut resistance test if excessive blunting of blade occurs during 1st test (Letters A to F with F being the best resistance). An X is displayed if this test is not needed.

6th Character (Optional): Impact resistance. (“P” if requirements are met)

KWF PROFI MARK

The “KWF Profi” mark is issued by The Kuratorium für Waldarbeit und Forsttechnik, a German research organisation.

“KWF PROfi” is a quality assurance mark which is attained after the products have gone through many months of testing with foresters in and around Europe.

UL MARK

The UL enterprise is a global safety science company based in the USA. They are a global leader in testing, inspection, certification, auditing and validation.

They audit our factory and products throughout the year and complete annual tests to ensure our USA/Canadian product is signed off and certified to their levels.